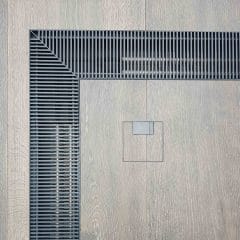

European Walnut Time Worn 4

Creating an aged look to a floor to this level requires real craftsmanship. Each walnut flooring board is carefully hand planed and distressed by hand so carefully that even worm holes are recreated. The finish for this particular engineered walnut flooring is a result of the unique evaporation process that the walnut itself is treated through, resulting in a smoother, more consistent style. Every board is individual and unique. The hand distressed range of walnut flooring are known for their high standard finish and excellent aesthetics, bringing elegance and style to any internal location. Similar to other styles of engineered walnut (including American walnut flooring) this style is built with a triple ply counterbalanced structure providing a very stable floor. Please note samples are not readily available for this product. Please visit our showroom to see a display board.

As special order and subject to availability we can now supply wide boards 240 – 500mm and lengths 2000 – 4000mm

Finish: Lacquered

Structure: Engineered 3 layer (same hardwood used for counter-balance layer), 2 layer Birch ply counter-balance layer)

Widths: 65, 90, 135, 165, 192, 240, 290, 340-390, 440-440mm

Thickness/Wear Layer: 11/4.2mm, 14/3mm, 14/4mm, 15/5mm , 20/5mm

Plank Lengths: 600, 700, 1200-2400, 1800-3200mm, longer on request

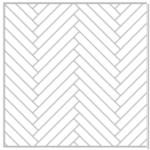

Herringbone: 90 x 700 x 14mm, 135 x 700 x 14mm

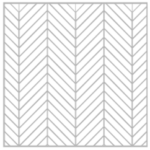

Chevron: 90 x 600 x 14mm, 135 x 700 x 14mm

Grades: Rustic AB, Rustic A, Prime

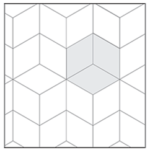

Formats: Plank, Herringbone, Chevron, Design Panels, Custom Shapes

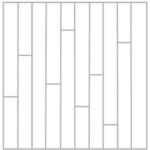

- Fixed Width Plank

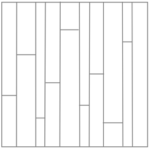

- Mixed Width Plank

- Herringbone

- Chevron

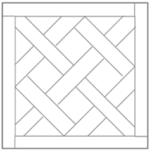

- Design Panels

- Custom Shapes

Aged Wood Flooring - Time Worn Finish Options

Time Worn 1

An incredibly realistic aged floor that reproduces the shrunken timber around knots that take centuries to evolve. Hand made soft rounded bevels and subtle surface textures make this floor truly unique. The surface is further enhanced with standard brushing of the surface with a wire brush to remove softer fibres and creating a natural texture of the surface that follows the grain of the timber. Suitable for rustic grades only and plank widths over 240mm wide

Time Worn 2

Similar to Time Worn 1 treatment but with a much more subtle unevenness. The surface is further enhanced with standard brushing of the surface with a wire brush to remove softer fibers and creating a natural texture of the surface that follows the grain of the timber. The edges of the plank on all 4 sides are made with standard machine made bevels. Suitable for rustic grades only and plank widths up to 290mm wide. Also suitable in Herringbone and Chevron floors.

Similar to Time Worn 1 treatment but with a much more subtle unevenness. The surface is further enhanced with standard brushing of the surface with a wire brush to remove softer fibers and creating a natural texture of the surface that follows the grain of the timber. The edges of the plank on all 4 sides are made with standard machine made bevels. Suitable for rustic grades only and plank widths up to 290mm wide. Also suitable in Herringbone and Chevron floors.

Time Worn 3

This treatment is achieved by hand working the timber to make deep unevenness of the surface around knots. The surface is further enhanced with heavy brushing of the surface with a wire brush to remove softer fibres and creating a natural texture of the surface that follows the grain of the timber. The edges of the plank on all 4 sides are made with standard machine made bevels. Suitable for rustic grades only and plank widths up to 500mm wide. Also suitable in Herringbone and Chevron floors.

Time Worn 4

Master craftsmen (and craftswomen) hand scrape the surface of the timber with a traditional hand plane as would have been used in centuries past. The surface has an irregular antique rustic look. Additional treatments include hand working wormhole effect to the floor. The edges of the plank on all 4 sides are made with standard machine made bevels. Suitable for rustic grades only and plank widths up to 500mm wide. Also suitable in Herringbone and Chevron floors.

Master craftsmen (and craftswomen) hand scrape the surface of the timber with a traditional hand plane as would have been used in centuries past. The surface has an irregular antique rustic look. Additional treatments include hand working wormhole effect to the floor. The edges of the plank on all 4 sides are made with standard machine made bevels. Suitable for rustic grades only and plank widths up to 500mm wide. Also suitable in Herringbone and Chevron floors.

| Width | |

|---|---|

| Colour | |

| Species | |

| Surface & Treatments | |

| Formats | Plank, Herringbone, Chevron 45°, Chevron 30°, Parquet Panels |

| Finish | |

| Wood Colour | |

| Style | |

| Format |